While working with Konel we participated in a food tech project called OPEN MEALS in which we produced edible 3D printed Japanese confectionaries. Cyber Wagashi were made with a 3D printer that uses a weather driven proprietary algorithm. Cyber Wagashi changes their shape and color depending on the wind speed, air pressure and temperature, which allows us to see, eat and enjoy the changes in the Tokyo sky each day.

As a part of Media Ambition Tokyo 2020, Cyber Wagashi was served at THE MOON, a restaurant in Roppongi.

OPENMEALS / Cyber Wagashi Project Video

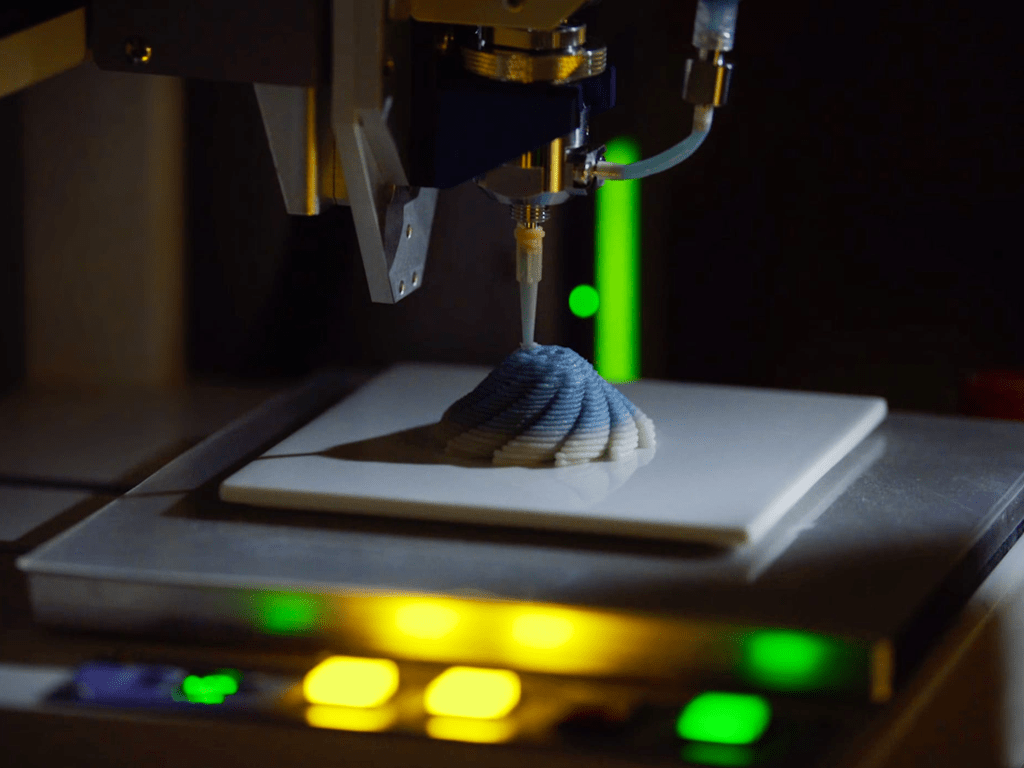

In this project I was responsible for figuring out how and what we could actually print using ingredients that would normally be used in traditional wagashi. I created multiple designs to be used as stress tests to figure out the strengths and weaknesses of both the printer and materials. From there I worked with our confectionary artist to get ingredients that were more stable for 3D printing and I worked with the 3D printer company to get some accessories and options to create a setup that could extrude the ingredients in a more predictable manner.

Once I had the 3D printer and wagashi ingredients working well together I worked with the art director on the project to discuss what types of designs would be printable and we went back and forth on a few different styles until we settles on the spiraling mountain shape. We chose this design because it was easy to alter different parameters of the design such as how many ridges, the amount of twist, height and diameter.

After the general design had been decided on, the software engineers at Konel developed an algorithm to automate making different shapes using current weather data. Meanwhile, I taught other team members how to operate and setup the 3D food printer so they could take over from there.

Cyber Wagashi 3D Printing Timelapse